What is NanoGAS®?

By generating bubbles of less than 1μm (micrometer) nanosize in a liquid and changing the gas trapped inside, NanoGAS® has been confirmed to be highly effective in maintaining the freshness of food, fermentation, promoting the growth activity of animals and plants, and special cleaning. These invisible bubbles are widely applied in various fields such as medicine, fermentation and brewing, special cleaning, iron and steel, cultivation and aquaculture, and beauty care.

The cloudy white bubbles often seen in bubble baths are called microbubbles or millibubbles, but in the case of NanoGAS®️, which has bubbles even smaller than those, the liquid is colorless and transparent to the eye.

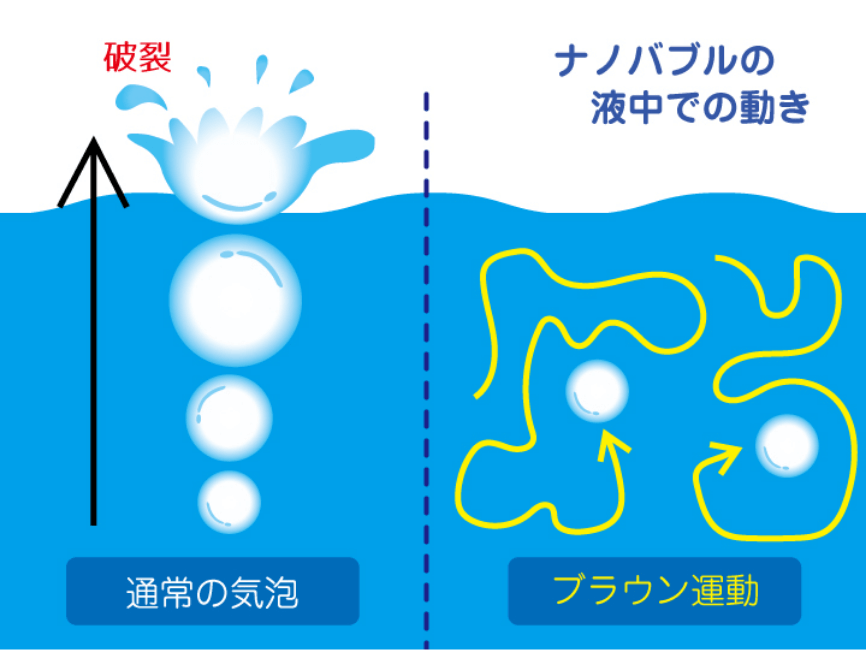

Millibubbles, such as champagne bubbles, are highly buoyant and escape rapidly into the atmosphere in a short period of time, but nano-sized NanoGAS®️ has almost no buoyancy and does not escape into the atmosphere.

In order for bubbles to dissolve more efficiently in liquids, it is necessary to maintain a state of equilibrium where “buoyancy” and “gravity” are in balance, which is achieved by NanoGAS®.

NanoGAS®, developed by Symbiosis Corporation, is the world’s first technology that makes it possible to keep bubbles in liquids dissolved for as long as 10 years.

It has various characteristics that differ greatly from microbubbles and millibubbles, and is attracting attention as a next-generation technology.

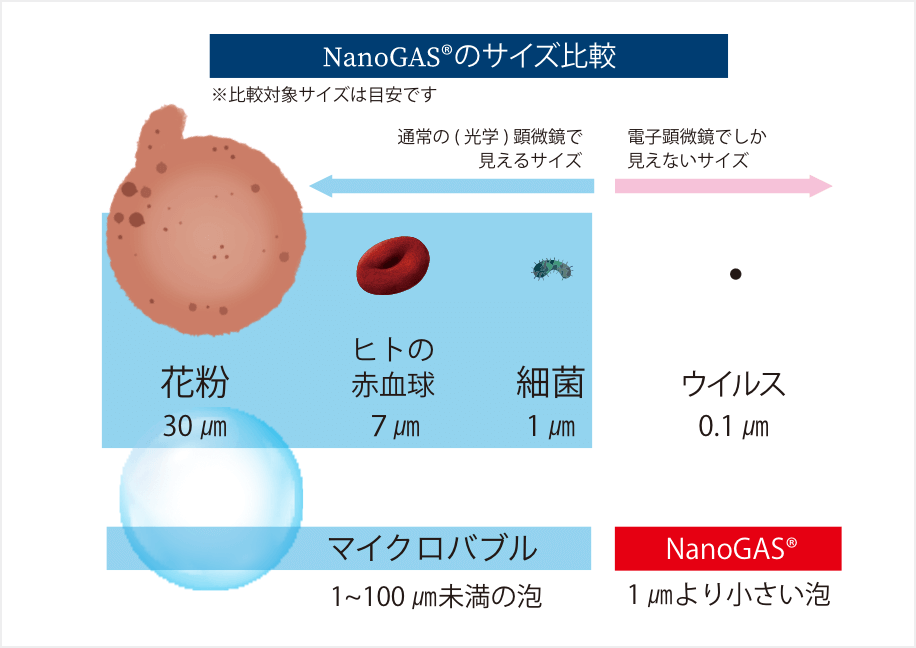

Invisibly small bubbles

Invisibly small bubblesOne thousandth of a meter is one millimeter (mm), one millionth of a meter is one micrometer (μm), and one billionth of a meter is one nanometer (nm). In other words, 1 nm (nanometer) is one billionth of 1 m (meter), which is larger than the difference between the diameter of the earth and that of a one yen coin.

Incidentally, bacteria are several micrometers in size and viruses are tens to hundreds of nm in size.

The gas dissolution and inclusion functions made possible by the ultra-fine bubbles of “NanoGAS®” are expanding the range of applications in a variety of fields, including pharmaceuticals.

A film of bubbles is a film of charges.

A film of bubbles is a film of charges.A unique feature of NanoGAS®️ is that the membrane covering the bubbles is a film of electric charges.

It is not a film of oil like a soap bubble, but is bordered by a liquid by the action of electrons.

In other words, NanoGAS®️ water is manufactured using only natural ingredients.

In addition, it can be utilized without additives or chemicals such as surfactants because it penetrates into the microscopic gaps between substances.

Physical adsorption/cleaning action (exfoliation action)

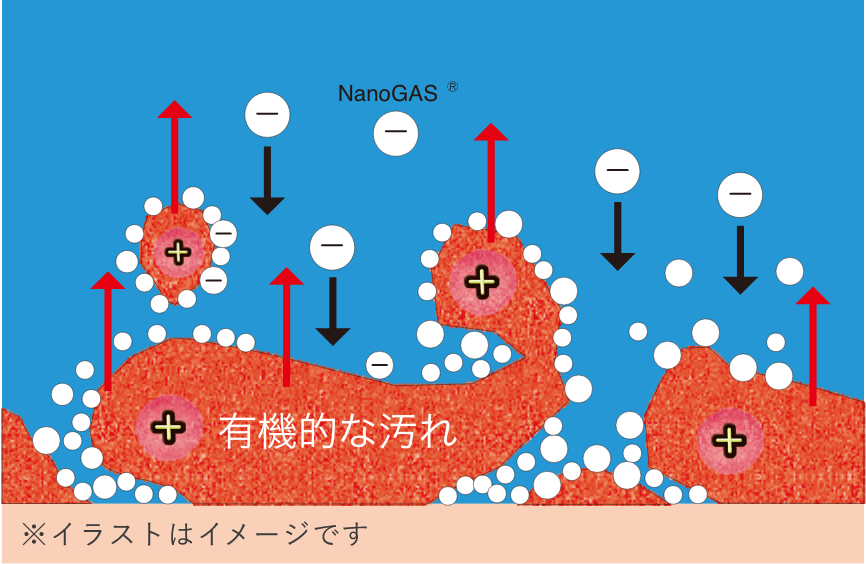

Physical adsorption/cleaning action (exfoliation action)Since NanoGAS®️ in water is negatively (minus) charged, bubbles repel each other and do not combine. Since the bubbles do not grow large, they can exist in the liquid for a long period of time.

The negative charge of the bubbles also allows them to lift up and peel off even the smallest dirt, since organic dirt is mainly positively charged. The bubble’s own crushing energy and the cross-linking action (surfactant action) it exerts when it encounters a substance enable efficient cleaning.

The redox potential of the liquid can be controlled by changing the density and size of the bubbles and the gases to be enclosed, as they have the property of lowering the redox potential of the liquid.

Bubble technology is expected to be used not only for cleaning, sterilization, and deodorization, but also in various industries such as steel, fisheries, and agriculture. While many companies are considering the potential of the technology itself, there have been reasons why the industry as a whole has not progressed in its application.

One of the reasons for this is the technical challenges involved (in long-term stability of the bubble).

Until now, the technical challenge of nanobubbles’ practical application has been the inability to stabilize bubbles in liquids and their disappearance. We have developed a technology that can stabilize bubbles in liquids for a long period of time by fundamentally reviewing existing nanobubble production technology.

The general nanobubble generator uses a technique called rotary shearing. We have patented equipment and manufacturing methods for both the rotating mixer and the bubble shear filter for the shearing portion of this process.

The combination of these patented technologies enables us to offer unrivaled quality.

We are in the process of applying for and obtaining patents for NanoGAS® technology in Japan and overseas.

Unfortunately, there is still no instrument in the world that can accurately measure bubbles of a few nm in size. We measured the number and density of particles using Beckman Coulter's Coulter counter method, which is currently the world standard for particle measurement

Although the number of bubbles has decreased after 10 years, a comparison of only bubbles with a lower detection limit of 200 nm or larger showed the presence of approximately 34% more fine bubbles of the same size. Compared to general bubble products, which are said to have a lifespan of several hours to several months, our NanoGAS® technology, which uses highly functional nanobubbles, has outstanding performance in terms of long-term stability. Change over time in NanoGAS®water particle counts

"I've honestly never seen numbers like these."

We received these words from the person in charge of the manufacturer, the world standard for particle measurement. We are not satisfied with our current technology and will continue to develop it. *The graph appears to be cut off in the middle because the minimum detection limit is 200 nm, but it is assumed that there are a large number of even smaller bubbles.

The high-performance nanobubble technology behind NanoGAS® is expected to be used in a great many fields as an environmentally friendly and safe “next-generation material” because it is multifunctional and requires only water and air as materials

Improved solubility of gases and solutes and the ability to contain a variety of gases

One of the properties of ultrafine bubbles is “self-pressurization”.

This is the action of an increase in the pressure inside a gas that allows the gas to efficiently dissolve into the liquid beyond its saturation level.

By changing the gas enclosed in the foam, it is possible to add additional functions to NanoGAS®️ water and maximize the properties of the gas.

Self-pressurization also acts to increase the saturated concentration of various substances (solutes) dissolved in the liquid (solvent) that holds the foam.

If your company is considering the introduction of NanoGAS® technology for the development of your own products, etc., please contact us.

We are pleased to announce that our "Nanobubble Generator" received the Director-General's Award of the Small and Medium Enterprise Agency in the 2022 Kinki Regional Commendation for Invention.

The "Local Commendation for Invention" was established in 1921 to honor engineers, researchers and developers who have created outstanding inventions, devices or designs in eight regions (Hokkaido, Tohoku, Kanto, Chubu, Kinki, Chugoku, Shikoku, and Kyushu).

Nanobubble dissolved fluid obtained by this invention and its production method is expected to be utilized to improve production efficiency and develop new technologies in many industrial fields, such as in the bacteria solution for gut flora transplantation, which is already in practical use, technology to accurately deliver target substances to organs, technology to efficiently extract active ingredients, and extremely high cleaning technology that does not require chemicals. This technology is expected to be utilized to improve production efficiency and develop new technologies in many industrial fields.

Small and Medium Enterprise Agency Director-General's Award

[Invention Name] Nanobubble Generator (Patent No. 7028499)

Makoto Shimizu, Researcher, Symbiosis, Inc.

Mikiko Tanaka, President and Representative Director, Symbiosis, Inc.

Our NanoGAS® series, whose core technology has been completed and is now in the verification stage in various fields, has been certified as an officially recommended product by the Japanese Society of Preemptive Clinical Medicine.